Molds are the tooling used in industrial production to form the required products by methods such as injection molding, blow molding, extrusion, die-casting or forging, smelting, and stamping. It mainly realizes the processing of the material shape through the change of its physical state.

The mold is a precision tool with complex shape and can withstand the expansion force of the blank. It has high requirements for structural strength, rigidity, surface hardness, surface roughness and processing accuracy.

The process performance of the mold material is one of the main factors that affect the production cost and manufacturing difficulty of the mold. Die steel is the main material used to make molds such as cold stamping dies, hot forging dies and die-casting dies. The performance requirements of die steel products include: strength performance (including hardness, red hardness, yield strength and compressive strength), toughness, wear resistance, thermal fatigue resistance and bite resistance.

Die steel is divided into three categories according to its purpose: hot work die steel, plastic mould steel, and cold work die steel. Hongsheng has the production capacity to provide multiple steel grades under the above three categories of die steels.

Related Products

HS DVN/ HS DVN-Nb Hot Work Die Steel

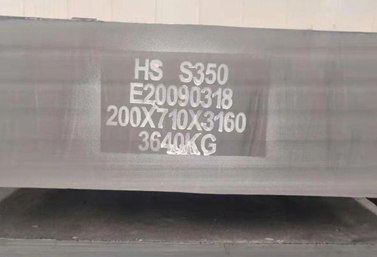

HS S350 Hot Work Die Steel

HS PH13 Hot Work Die Steel

HS H13-MOD Hot Work Die Steel

HS PH11 Hot Work Die Steel

HS 2343ESR-S Hot Work Die Steel

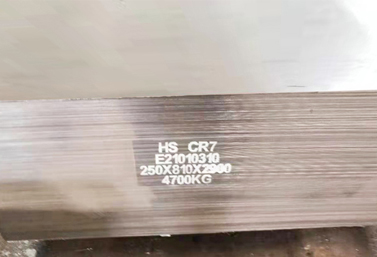

HS CR7 Hot Work Die Steel

HS 2344 Hot Work Die Steel

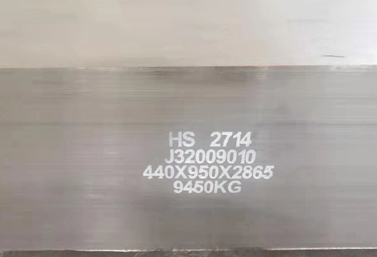

HS 2714 Hot Work Die Steel

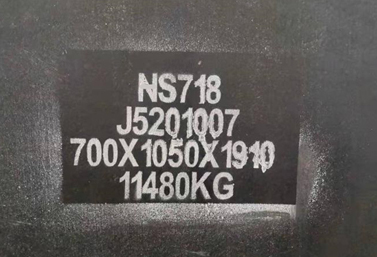

HS 718 Plastic Die Steel

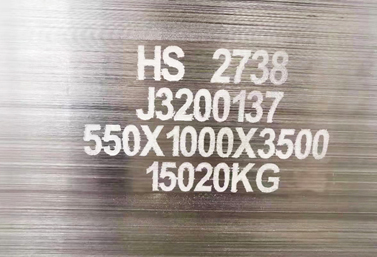

HS 2738 Plastic Die Steel

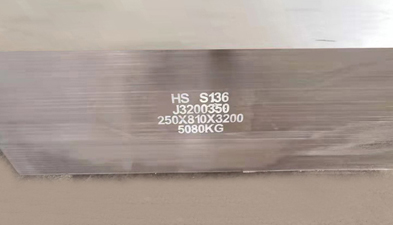

HS S136 Plastic Die Steel

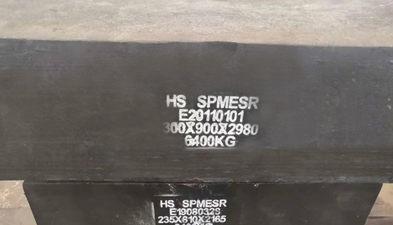

HS SPM / HS SPM ESR Plastic Die Steel

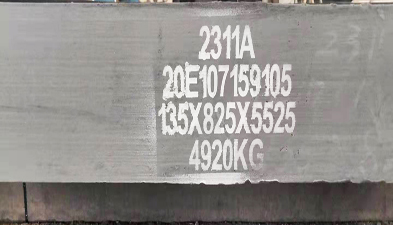

HS 2311 Plastic Die Steel

HS DC53 Cold Work Die Steel

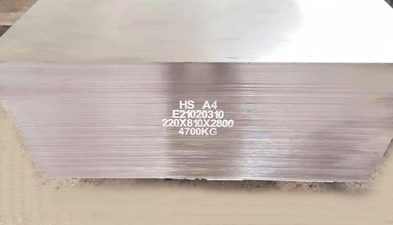

HS A4 Cold Work Die Steel

More Application

Focus on manufacturing special steel cast and forged

components for more than 25 years.