As modified improved high-thermal-strength hot-work die steel, HS H13-Mod of material H13 equivalent, optimizes the ratio of C and Cr alloy elements on the basis of traditional H13, reduces the content of harmful elements such as P and S, so that H13 equivalent has good thermal stability and thermal fatigue resistance. HS takes pride in presenting a premium selection of high-quality H13 steel for sale, catering to a diverse range of industrial applications. At HS, we offer H13 material steel that meets stringent quality standards, ensuring optimal performance in challenging environments.

Steel Grade | C | Si | Mn | P | S | Cr | Mo | V |

HS H13-Mod | 0.30~0.40 | 1.20~1.60 | 0.30~0.50 | ≤0.015 | ≤0.003 | 3.50~4.50 | 0.80~1.20 | 0.80~1.00 |

HS H13-MOD is an advanced and modified version of H13 steel, designed to offer superior properties in comparison to its traditional counterpart. Recognized as a material H13 equivalent, HS H13-MOD incorporates specific modifications in its composition to enhance key characteristics, making it a preferred choice for demanding applications in the realm of tool and die manufacturing.

As a H13 equivalent material, HS H13-MOD retains the foundational attributes of H13 steel while introducing refinements that elevate its overall performance. These modifications are tailored to enhance critical features such as toughness, heat resistance, and wear resistance, addressing the evolving needs of industries requiring robust tooling solutions. The "H13 equivalent material" designation underscores the compatibility of HS H13-MOD with established industry standards, providing a seamless transition for applications where H13 steel equivalent is conventionally employed.

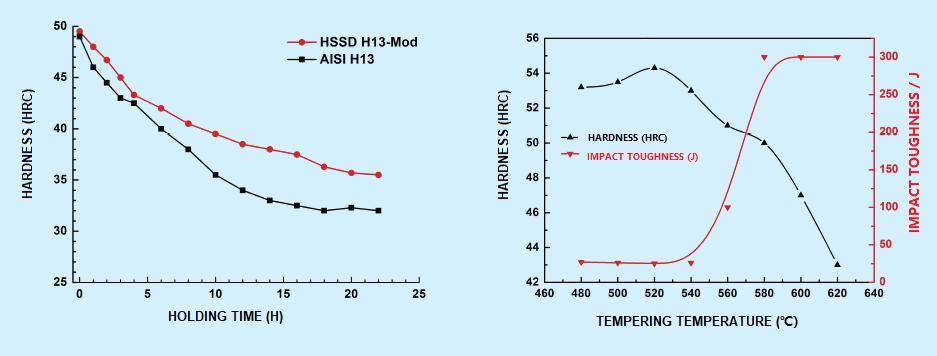

High resistance of tempering softening properties (the using temperature can improve 50℃ comparing with H13 steel).

Excellent Thermal Stability: the moulding die manufacturing of the H12-MOD can be under long time preservation of 620℃, the hardness is always higher than that of H13, and still maintain above 35HRC.

High thermal fatigue resistance: better than that of H13 steel.

Performance curve of tempering and CCT curve (continuous cooling transformation).

Heating Temperature/℃ | Cooling Way | Hardness (HRC) | Tempering Temperature/℃ | Tempering Numbers | Hardness (HRC) | ||

First Preheating | Second Preheating | Last Heating | |||||

500~600 | 820~860 | 1010~1060 | Oil Cooling | 53~55 | 560~600 | 2~3 | 47~50 |

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.