Oue company strive to supply high quality of cold work die steel, and the HS DC53 is an important one.

As high-toughness high-wear-resistance cold work die steel, HS DC53 equivalent, can be applied to stamping dies and cold forging dies, which is dc53 steel equivalent, 1.2990 steel, sld-magic and assab 88.

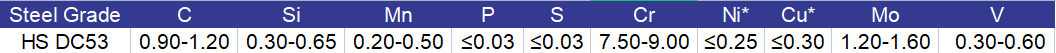

* residual content allowed

DC53 steel, the assab 88 steel equivalent, is a high-performance cold work tool steel that has gained popularity for its exceptional properties in various industrial applications. Developed as an improvement over traditional tool steels, DC 53 steel offers a combination of high toughness, wear resistance, and excellent machinability, making it well-suited for demanding applications in tool and die making.

Our material DC53 steel and DC53 steel equivalent can be used to conduct precision stamping dies, cold forging, deep drawing, and thread rolling die, auto parts bending dies, bicycle parts dies, hydraulic forming dies, high-speed blanking punches, stainless steel plate punches, etc.

The material DC53 steel and its equivalent material has high toughness, high wear resistance, and good high-temperature anti-tempering stability, and has a small risk of chipping or cracking during use.

| QUENCHING | TEMPERING | |||||||

| Prog-ram | Heating Temperature/℃ | Cooling Way | Hardness(HRC) | Tempering Temperature /℃ | Tempering Numbers | Hardness(HRC) | ||

| First Preheating | Second Preheating | Last Heating | ||||||

| Ⅰ | 500~600 | 820~860 | 1010~1060 | Oil Cooling | 60~65 | 170~230 | 2 | 61~63 |

| Ⅱ | 500~600 | 820~860 | 1010~1060 | Oil Cooling | 60~65 | 510~540 | 2 | 60~62 |

DC53 Steel Equivalent Material

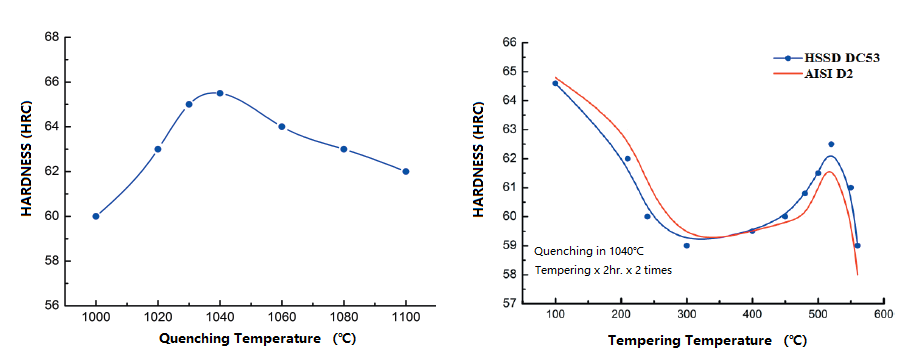

DC53 special steel and its equivalent material are a new type of cold work die steel from Japan Daido steel, improved on SKD11. The heat treatment hardness of the DC53 steel is higher than SKD11, reaches 62-63HRC after tempering at 520-530℃. DC53 exceeds SKD11 in strength and wear resistance, and the toughness is twice that of SKD11, which is more prominent in cold work die steel. The tools made of DC53 rarely have cracks, which greatly improves the service life.

You can find DC53 steel equivalent to ASSAB 88 / Cr8Mo1VSi from GB/T standard / modified A8 from FINKL / SLD8 from HITACHI / K340 from BOHLER

Exceptional Toughness

One of the primary advantages of DC53 steel is its exceptional toughness. This property allows tools made from DC53 to absorb impact and resist chipping or cracking, contributing to increased durability and longevity in service.

High Hardness

DC53 exhibits high hardness, enhancing its resistance to wear and abrasion. This makes it well-suited for applications where tools are subjected to repetitive friction and contact with abrasive materials.

Excellent Wear Resistance

The steel's composition and heat treatment contribute to excellent wear resistance, making DC53 suitable for tooling applications where extended tool life and reduced wear are crucial factors.

Superior Machinability

DC53 steel is known for its superior machinability. This characteristic facilitates the efficient and precise machining of intricate tooling components, contributing to the overall manufacturing efficiency.

Good Heat Treatment Response

DC53 responds well to heat treatment processes, allowing for the optimization of its mechanical properties. This adaptability makes it versatile in meeting specific application requirements through controlled heat treatment.

Related Products

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.